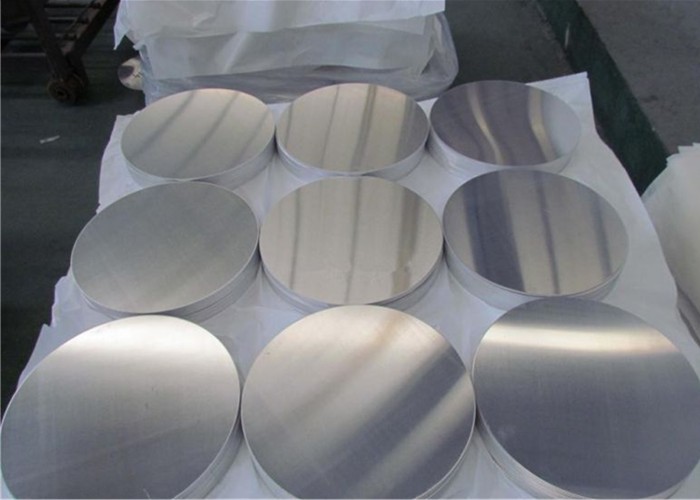

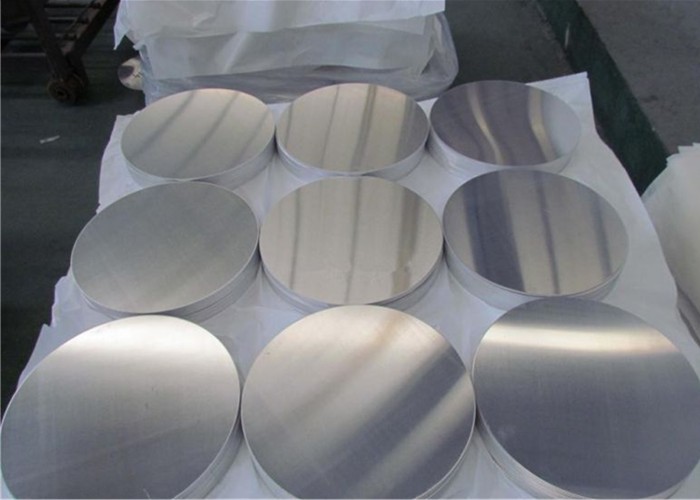

1070 1000 Aluminium Discs Circles For Cookware

Product attributes

| Product name | Aluminum Alloy Wafer |

| Color | Silvery |

| Shape | Round |

| MOQ | 1Ton |

| Sample | Freely |

| Size | Costomization |

| Alloy | 1050 1060 1070 1100 |

| Material | Aluminum Alloy Metal |

| Standard | GB/T3880 ASTM B209 |

| Package | Strong Sea Worthy Wooden Package |

Product display

Introduction to annealing of aluminum circle

1. Annealing of aluminum veneer

The annealing of aluminum veneer is divided into complete annealing

and low temperature annealing. Its purpose is to control the final

performance of aluminum veneer products and ensure that aluminum

veneer products meet the requirements of technical standards.

Complete annealing is used to produce soft products; low

temperature annealing is to eliminate internal stress, stabilize

material size, shape and properties, so as to obtain semi hard or

hard products. The annealing process of finished product is more

strict than that of intermediate annealing.

2. Complete annealing of aluminum sheet

The complete annealing temperature is 100 ~ 200 ° C higher than the

recrystallization temperature

In order to prevent grain coarsening, or surface oxidation,

gettering, and reduce recrystallization texture, the upper or lower

annealing temperature should be reduced as much as possible. For

the same aluminum sheet alloy, the appropriate annealing

temperature should be determined according to different annealing

equipment, product specifications, cold deformation, technical

requirements and charging capacity. For the holding time,

generally, the longer the holding time is, the more the charge, the

thicker the product or the more uneven the temperature

distribution. Heating speed in the premise of ensuring quality, it

is best to use fast heating method. On the one hand, it can shorten

heating time, save energy and improve productivity; on the other

hand, it can refine grain and improve product quality. The cooling

rate is the same as that of intermediate annealing.

FAQ

1. who are we?

We are based in Henan, China, start from 2014,sell to South

America(21.00%),North America(19.00%),Eastern

Asia(18.00%),Africa(16.00%),South Asia(15.00%),Southeast

Asia(10.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Aluminum alloy 1 Series,Aluminum alloy 3 Series,Aluminum alloy 5

Series,Aluminum alloy 8 Series,Aluminium Circle

4. why should you buy from us not from other suppliers?

Advanced equipment for aluminum wafer production base.The most

professional aluminum wafer.We are a factory, not a trader.Our

products have excellent tensile properties. quality. Low price.

Thickness tolerances are also very small.

5. what services can we provide?

Accepted Delivery Terms:

FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express

Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,CAD,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit

Card,PayPal,Western Union,Cash,Escrow;

Language

Spoken:English,Chinese,Spanish,Japanese,German,French,Russian,Korean