Hobe Aluminium is professional in manufacturing Aluminium Circle.

Mainly producing Pure Aluminum Circle, like Alloy 1050, 1060, 1070,

1100 and Alloy Aluminium Circle, like Alloy 3003.

We are located in famous aluminium capital of Zhengzhou City, Henan

Province. By using such kind of regional comparative advantage, we

orient to provide the customers with high quality and substantial

products at lowcost. Our Aluminium Circle is widely used in

cookware, kitchenware, utensils, pot, kettle, non-stick pan, basin,

bucket, frypan, tray, pressure cooker, traffic signs, furniture,

lighting, lampshade, etc.

We would like to highlight our Aluminium Circle, with good physical

performance, flat surface and smooth edge, Suitable for both

deep drawing and Spinning.

We enjoy a good reputation among our customers for our aluminum

circle with high quality and competitive price; win high

appreciation from our clients with the excellent workman-ship

and professional ability. The quality matches with ISO 9001

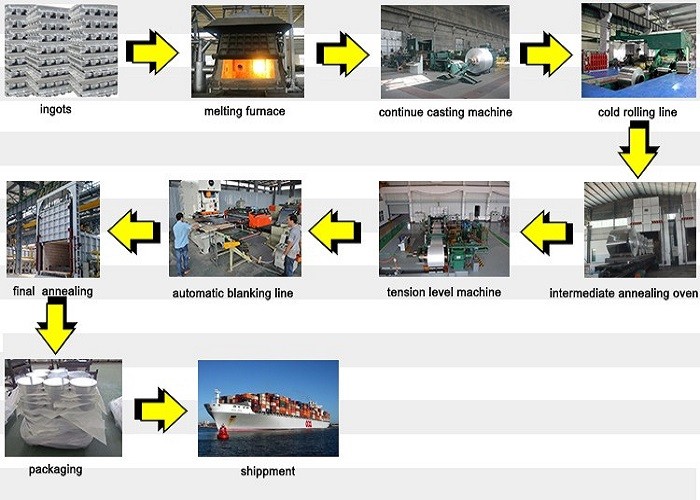

quality management system. We have 3 aluminium circles

production line, and the annealing equipment.

Our motto and mission is to offer best service for our customer

with Heart and Soul.